Fires can always happen. Preventive measures in structural fire protection can contain the spread and therefore the damage. A particular hazard occurs when unsecured pipe penetrations promote the spread of fire and smoke in a building. The German manufacturers from the Blue Responsibility initiative are therefore continuously working on sustainable solutions for optimising fire protection, increasing safety and retaining the value of properties.

In case of a fire, flames, smoke and heat will mercilessly exploit any weak points in the building. Building regulations for fire protection consequently focus on securing escape routes and rescue paths as well as on preventing the flames from spreading and on keeping the damage as small as possible. If ceilings or walls are defined as fire compartments, for example, shafts or pipe penetrations into a neighbouring fire compartment must not let fire and smoke penetrate prematurely. The applicable building codes and valid technical building regulations define the respective fire protection measures, e.g. regulations for pipework and ductwork. The German sanitaryware industry is continuously developing products which combine fire protection requirements with practical application in plumbing.

Viega, for example, offers a number of tested pipe collars which were tested with neighbouring systems. “The usability certificate in the form of a general building control test certificate is available and allows practical installation while respecting the requirements of fire protection,” Dirk Thielker from Viega explains. Another practicable example is the variable shaft and pre-wall system from Geberit. The action of the fire protection with regard to vertical and horizontal spread was confirmed for this system through fire testing for the entire construction process. “By combining sanitary, heating, ventilation, wastewater and electric lines as well as the structural frame, our system simplifies and speeds up the construction process while complying with all relevant fire protection and sound insulation requirements,” Volker Röttger from Geberit explains.

Securing escape and rescue paths

In case of a fire, the physical well-being of everyone in the building has top priority. Safe pipe systems in escape and rescue paths play an important role in this. Suitable solutions are, for example, metal pipe systems from Viega which can be installed open without any further requirements. Plastic pipe systems can also be used. “The prerequisite for this is a fire protection encapsulation of the pipe system for at least 30 minutes. This can be achieved by insulating the pipes, e.g. with a Rockwool RW 800 pipe collar,” Dirk Thielker explains.

Safe distance for maximum fire resistance

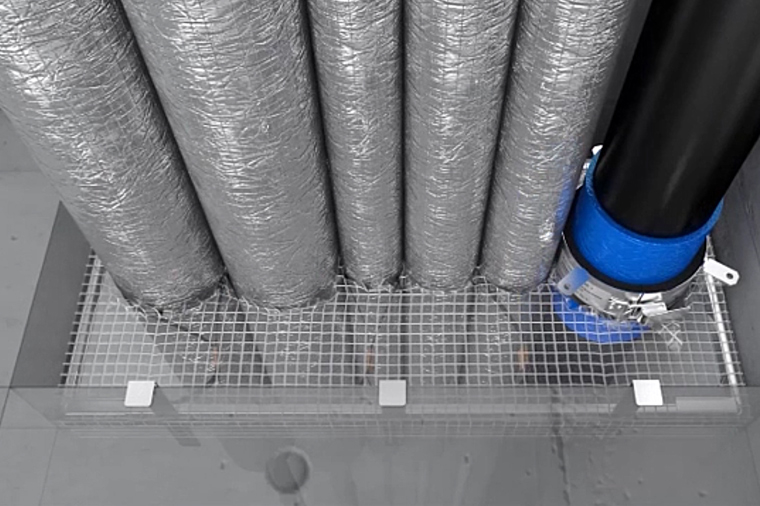

The regulations stipulated by the DIBt (German Centre of Competence for Construction) and the MLAR (German regulation on fire safety of conduit installations) govern the minimum distances between cable and pipe seals as well as other openings and installations such as ventilation ducts. If these distances are not observed, the stated fire resistance classes may be decreased substantially. For media lines together and with other penetrating elements, minimum distances in line with MLAR and/or the applicable usability certificates have to be observed. These standards refer to pipe systems and installation shafts penetrating through fire-resistant building elements in basements and upper floors. Particularly in housing construction, hotels or retirement homes, where usable floor space is a priority, a classic F90 shaft would become infeasibly large if the minimum distances were adhered to. Manufacturers of construction products therefore have certain systems tested in conjunction to prove that the required distances are not necessary. Viega, for example, offers fire seals which can be installed with zero gaps within their system but also in combination with all standard pipe systems. “A lot of patience is needed, particularly when it comes to testing third-party systems. The required test reports, certificates and approvals can take up to four years and are very cost-intensive. Nevertheless, these solutions are of great importance with respect to feasibility of the installation,” Dirk Thielker explains.

Checking usability and conformance certificates

The lengthy path from the testing of a fire protection product to the issuing of the usability certificate makes it exceedingly difficult to implement adaptations quickly. In addition to the usability certificates, conformance declarations for construction products and construction types are required to confirm that these comply with technical regulations, test certificates and approvals. “A type, e.g. a pipe, its fixing or its insulation, consists of different construction products. The type is usually fabricated by the installer, but several installers may be involved in the fabrication of the type,” Thielker explains. The manufacturer of the construction product is indicated on the applied Ü-mark or on the CE-mark and declaration of performance of the usability certificate.

Despite precise regulations, deviations from usability certificates can hardly be avoided in reality. “In this case it is important to coordinate all trades early on before construction starts,” Röttger stresses. Ascertaining compliance or deviation of a construction product is the responsibility of the manufacturer of the product. If they assess the deviation as insignificant, this is regarded as compliance with the usability certificate. This accordingly applies to construction types where it is implemented by the fabricator of the type, i.e. the installer. “If the installer is unsure about the assessment of a deviation, they can contact either the owner of the usability certificate or a testing body,” Thielker recommends.

Raising profiles in the market through fire protection know-how

Fire protection is often perceived as complicated by tradesmen. “This is due to numerous interfaces with different trades as well as to a flood of European regulations and insufficient capacities at the responsible authorities. Planners and installers should not regard fire protection as a necessary evil, but as an opportunity to raise their profile through comprehensive know-how in the market,” Röttger recommends. Wolfgang Burchard from Blue Responsibility also confirms: “Only properly implemented fire protection measures and their correct documentation can ensure the required level of fire protection and the proof of correct usability. Fire protection measures in plumbing can then substantially support the long-term value retention of a property as well as the safety of its occupants and visitors.”

Learn more about the issue on the manufacturers' websites www.geberit.de and www.viega.de.